- Pandemic is highlighting that recycling is now essential to U.S. manufacturing

- Investors are boosting funding of startups that promise to improve the sorting of waste to reclaim useable materials

- A clearer understanding of the importance of recycling may help the move to a circular economy to cut down on greenhouse emissions and combat climate change.

The deadly coronavirus epidemic is changing the image of recycling from something we do to help the environment to being a critical part of U.S. manufacturing.

When the Department of Homeland Security designated manufacturing as one of 16 critical infrastructure sectors, recycling companies saw themselves as integral to the sector’s supply chain and stayed open. That makes sense, since McDonald’s, Colgate-Palmolive, and Verizon among the hundreds of U.S. companies committed to using recycled materials.

“Industries are making a strong case that the recycling and processing facilities are essential,” Scott Mouw, senior director of strategy and research at the Recycling Partnership, a nonprofit that works with communities to improve their recycling. “Manufacturers have committed to recycled materials. The pandemic doesn’t take us off track to the circular economy.”

A large-scale move by manufacturers and other businesses toward using recycled materials has long been supported by environmental groups as a way to combat climate change and protect the Earth. Creating a circular economy could address as much as 55% of the greenhouse emissions that are produced, according to a report from U.K. charity Ellen MacArthur Foundation.

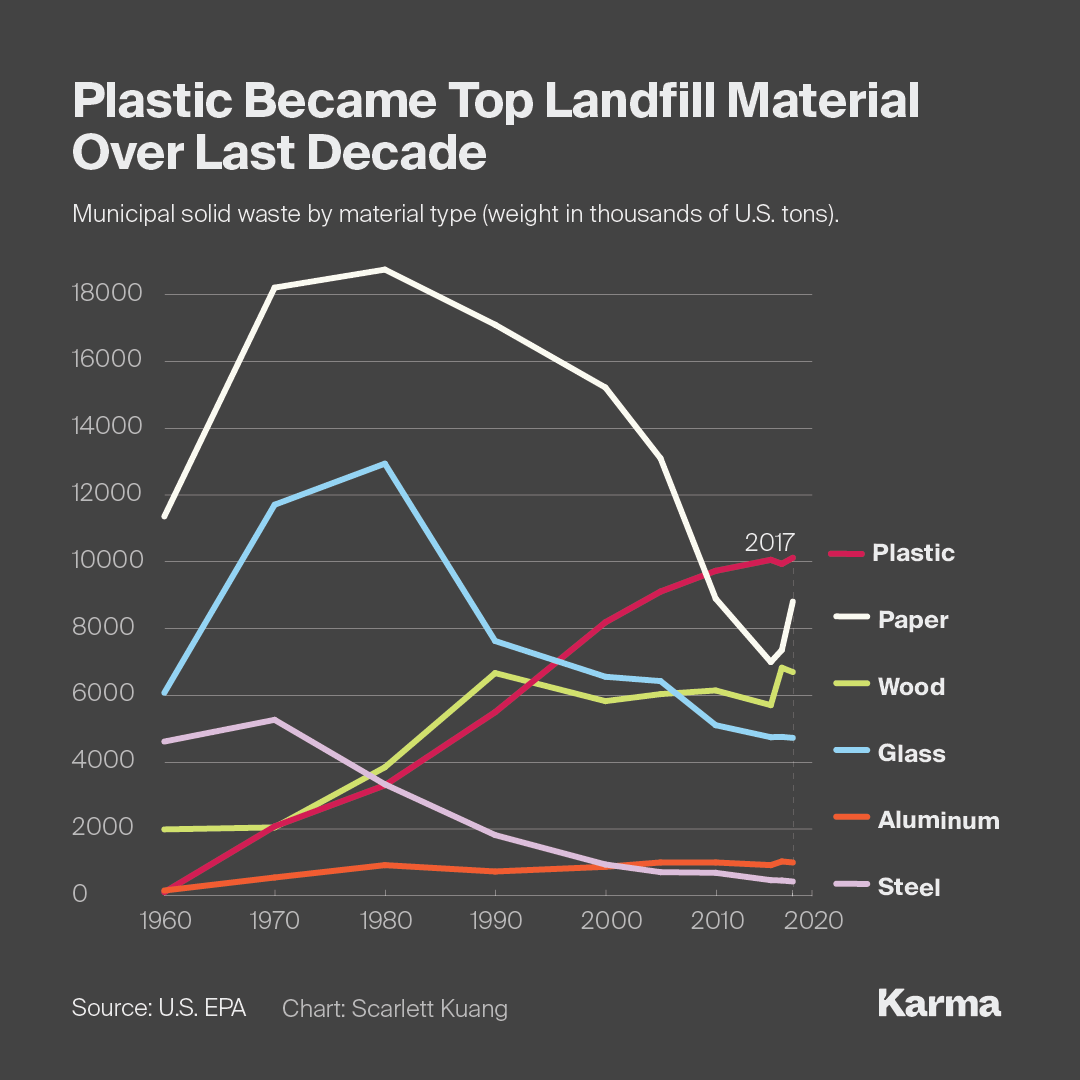

It would also cut down on global waste, which is expected to increase from 2 billion metric tons annually in 2016 to 3.4 billion metric tons in 2050, according to the World Bank. The U.S. could do more to help, since the recycling rate is only a bit over 35%, according to the Environmental Protection Agency’s latest figures.

Investors have been putting cash into companies that can more efficiently sort waste and recapture recyclable materials. Two startups have raised $11 million so far this year, more than three-fold of the same time last year, according to PitchBook data.

Innovation is needed because much of the recycling infrastructure in the U.S. was built to manage packaging that was around 20 to 30 years ago, Dylan de Thomas, VP of industry collaboration of the Recycling Partnership, told Karma in November. Packaging has become more complex and the facilities haven’t kept up.

Companies that have committed to the circular economy can’t go back to the way they did things before without a lot of costs and time, said Steve Alexander, president of the trade organization Association of Plastic Recyclers. “The machines that make paper napkins, toilet tissues, for example, that are set up to use reclaimed materials,” he said. “They can’t just switch over to virgin materials.”

In fact, he told Karma, recycling in the U.S. needs to increase dramatically to fill the needs of manufacturers once the pandemic ends and factories start gearing up again.

“The demand is going to be there,” he said. “We need to collect more material.”

While some communities like Somerset County, New Jersey, have cut back on recycling, only a small minority of programs have been curtailed across the country, Mouw said. He expects those programs will resume once the pandemic eases.

“Recycling is increasingly seen as an essential service,” Mouw said. “Consumers see recycling is a service that they expect, like sewers.”

Photo by Spencer Platt/Getty Images